|

|

|

|

Pretreatment ChemicalsHow do I clean up a new water system?

The cleaning of water systems for oil and grease removal is very important as these contaminants can cause severe loss of heat exchange capacity. In addition, the areas of deposition are excellent sites for corrosion cells to form and places where microbiological growths can breed and multiply causing severe fouling problems. Thus, new systems must be cleaned to remove oils, greases and foulants that may remain on the system surfaces after processing and erection.

Also, if these systems become contaminated while in service due to process leaks or other contamination, these deposits should be cleaned as quickly as possible to prevent the aforementioned problems. The program and product recommended below has been developed specifically to insure all the common metallurgies found in these systems (carbon and stainless steels, iron, copper and copper alloys, aluminum, galvanizing, etc.) are not effected by the cleaning.

What is the cleaning procedure?

Prior to cleaning, the system should be flushed to remove as much loose and/or suspended matter as possible. In an operating system, this can be accomplished by blowdown and being careful to add makeup to replace the water lost by blowdown. Then the procedure can be initiated:

- Where possible, heat the water in the system to 130º to 180º F. Heating speeds the reaction and reduces the time and/or the concentration of the cleaning solution required to clean the system.

- Add Q-ALK PC at the rate of 0.5-1.0% (i.e. 0.5-1.0 gals./100 gals. water contained in the system).

- If the system water is heated to the recommended temperature, cleaning should be completed in 12-24 hours. Where heating is not possible, the solution can be safely circulated in the system for several days.

- The system should now be drained and flushed with plain water until the flushing remains clear. If the cleaning is done while the system is in operation, the flushing may be done by blowing down heavily while refilling at the same time.

- When the system has been thoroughly flushed, immediately charge it with the standard treatment package.

NOTE: For some severely fouled systems, it may be necessary to repeat the cleaning procedure.

The raw materials for this product is in stock, but it is manufactured to order per ISO specifications. Lead time on production is 4 to 7 days. Product ships from our Virginia manufacturing partner.

Since the product is manufactured to order, we can not provide expedited orders.

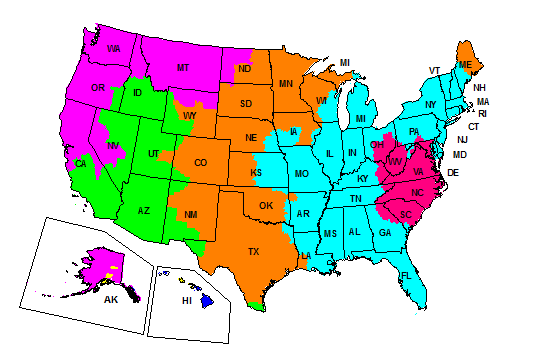

See transit times map below:

Free shipping transit times map (After Production).

Remember production time is 4 to 7 days. This map is transit time.

You will receive your tracking number within a week after ordering.

|

|

|

|

|

|

|